Quality Frameworks and Certifications

Standards & Certifications Overview

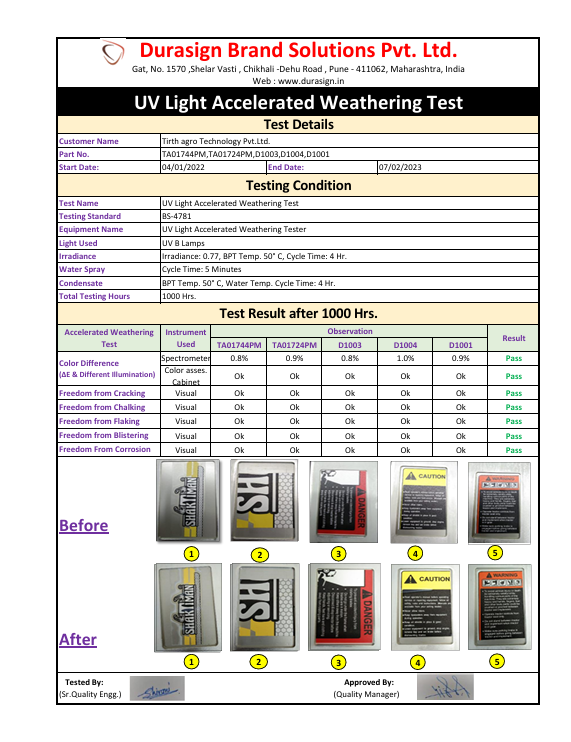

UV Light Accelerated Weatherometer Testing

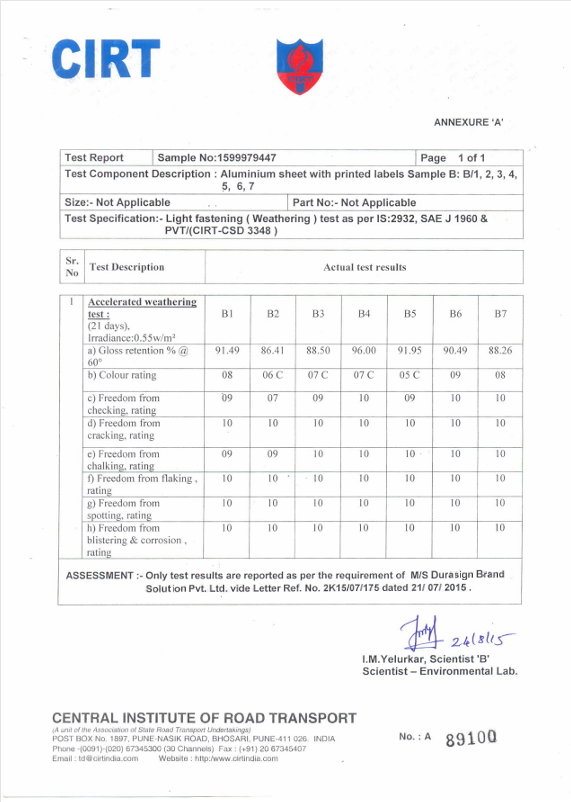

Central Institute of Road Transport Certification

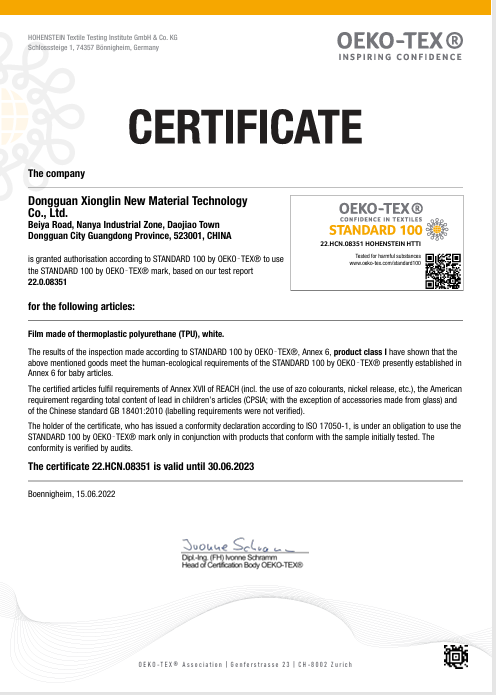

Oeko-Tex Certification

Intertek Certification

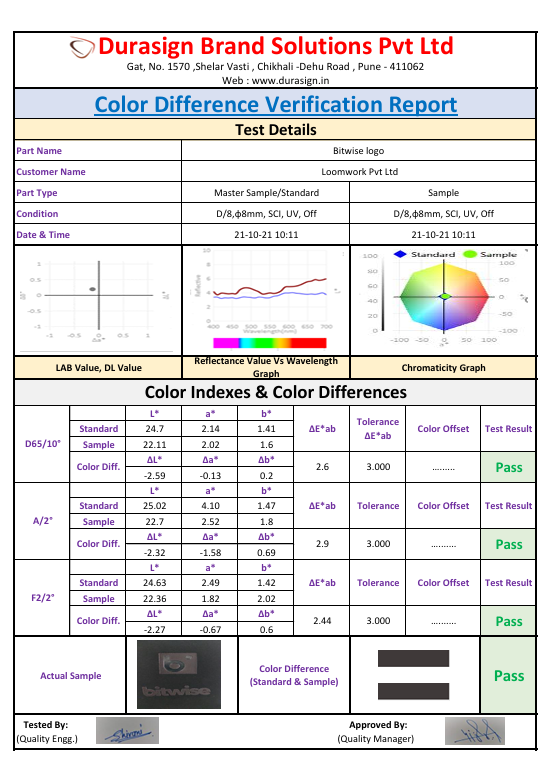

Colour Difference Test

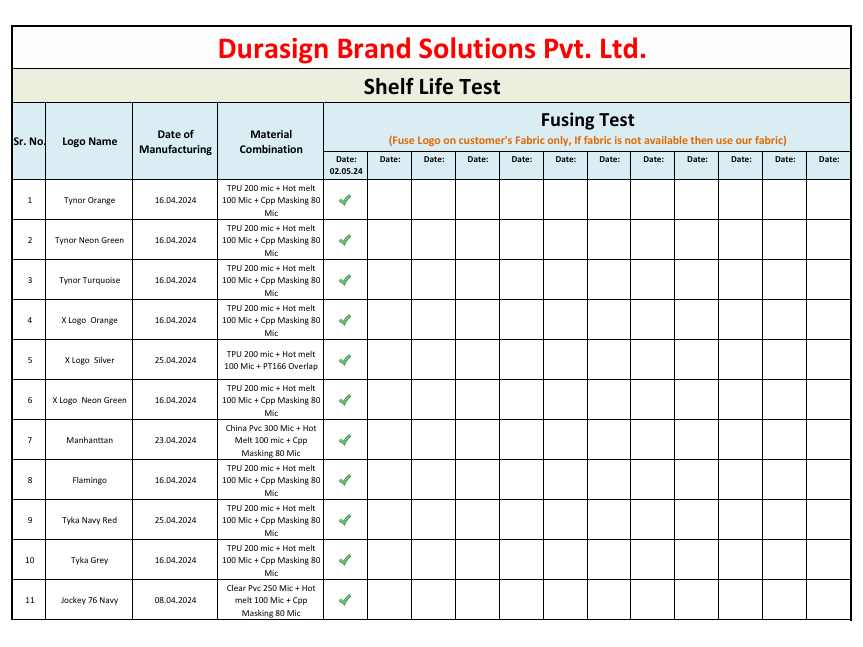

Shelf Life Test

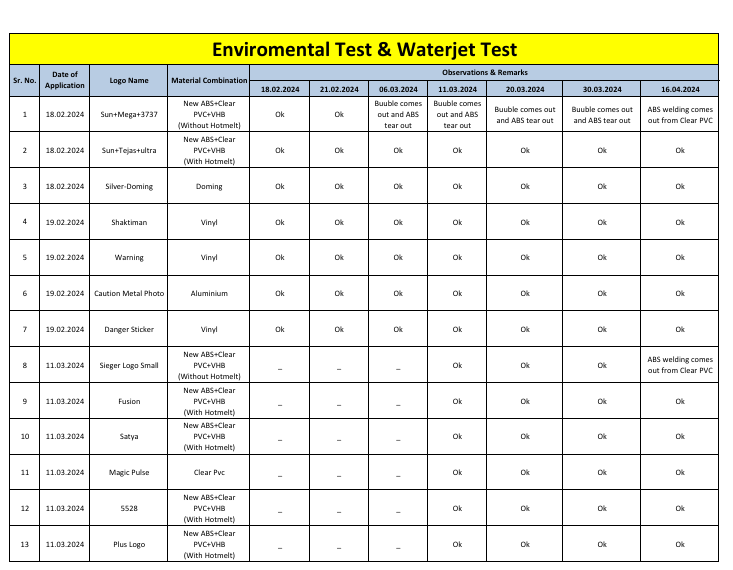

Environmental and Waterjet Tests

UV Light Accelerated Weatherometer Testing

- Simulates Outdoor Weathering: This testing method replicates prolonged exposure to sunlight, especially UV radiation, to simulate real-world environmental effects on materials.

- Evaluates Durability: It helps assess the long-term durability of products like coatings, plastics, and fabrics when exposed to UV light, heat, and moisture.

- Accelerated Aging: UV testing accelerates the aging process, allowing manufacturers to quickly predict how a material will perform over years of outdoor exposure.

- Material Degradation Analysis: The test highlights potential issues like cracking, fading, yellowing, or loss of mechanical properties in materials.

- Product Development: Helps in developing UV-resistant products by understanding which materials withstand prolonged UV exposure.

- Standards Compliance: Many industries require UV testing to meet specific quality standards for outdoor products like paints, automotive parts, and construction materials.

- Cost and Time Efficient: Offers a quicker and more cost-effective alternative to natural outdoor exposure testing, which can take months or years.

- Reproducibility: Results from accelerated weathering tests are consistent and reproducible, providing reliable data for material performance.

- Environmental Impact Simulation: In addition to UV light, the test can also simulate other environmental factors like humidity, temperature fluctuations, and rain.

- Product Warranty Validation: Manufacturers use these tests to determine the lifespan and durability claims for their products, ensuring that warranty periods are appropriate.

CIRT Certification

- Regulatory Compliance: CIRT (Central Institute of Road Transport) certification ensures that vehicles and automotive components comply with Indian government safety, environmental, and performance standards.

- Vehicle Safety Assurance: It tests various safety parameters like braking systems, steering, and vehicle structural integrity, ensuring the safety of vehicles on the road.

- Emission Standards Compliance: The certification ensures that vehicles meet Indian emission norms (BS VI, for example), helping reduce air pollution and promoting environmentally friendly practices.

- Quality Benchmark: CIRT certification acts as a quality benchmark for manufacturers, proving that their products meet the required performance and reliability standards.

- Eligibility for Government Tenders: Manufacturers with CIRT-certified products can participate in government tenders for supplying vehicles or automotive parts.

- Mandatory for Public Transport Vehicles: For buses, trucks, and other public transport vehicles, CIRT certification is mandatory before they can be registered and operate on Indian roads.

- Supports Export: CIRT certification adds credibility to Indian automotive products, making them more acceptable in international markets where safety and emission standards are essential.

- Component Certification: Apart from complete vehicles, CIRT certifies critical automotive components like axles, brakes, tires, and other parts, ensuring their safety and compliance.

- Encourages Innovation: By adhering to stringent standards, manufacturers are encouraged to innovate and improve vehicle technologies, making them safer and more efficient.

- Market Trust and Credibility: CIRT-certified vehicles or parts are viewed as more reliable by consumers and businesses, enhancing trust and brand reputation in the market.

Oeko-Tex Certification

- Consumer Safety: Oeko-Tex certification ensures that textiles and fabrics are free from harmful substances, making them safe for human use, especially in contact with the skin.

- Chemical Control: It verifies that the certified products meet stringent limits for harmful chemicals, such as heavy metals, formaldehyde, pesticides, and phthalates.

- Environmental Responsibility: The certification promotes sustainable textile production by controlling the use of chemicals that could harm the environment during manufacturing.

- Global Standard: Oeko-Tex is a globally recognized certification, offering consistency and trust in the textile supply chain across different countries.

- Enhanced Product Credibility: Brands with Oeko-Tex-certified products are viewed as more credible and environmentally conscious, helping them build customer trust and loyalty.

- Compliance with Regulations: The certification ensures compliance with international regulations, such as the EU’s REACH regulation, helping manufacturers avoid legal issues related to chemical safety.

- Wide Range of Products: Oeko-Tex certification covers a wide array of products, including clothing, home textiles, upholstery, and children’s items, broadening its applicability in the market.

- Sustainable Supply Chain: It encourages manufacturers to adopt safer, more eco-friendly processes throughout the textile production chain, reducing the overall environmental footprint.

- Supports Market Differentiation: Certified products stand out in the market by offering an added value proposition of safety and environmental responsibility, appealing to eco-conscious consumers.

- Boosts Export Opportunities: Oeko-Tex certification is well-recognized worldwide, allowing manufacturers to access international markets where safety and environmental standards are stringent.

- Regular Testing and Audits: Continuous testing and annual audits under Oeko-Tex help maintain the high safety and quality standards, ensuring ongoing compliance.

- Health and Wellness Impact: The certification is especially significant for products targeting sensitive groups like babies, children, and individuals with allergies, ensuring minimal risk of allergic reactions or health hazards.

Intertek Certification

- Quality Assurance: Intertek certification ensures that products meet high-quality standards in terms of performance, safety, and reliability, providing assurance to both manufacturers and consumers.

- Global Market Access: Intertek certification is recognized internationally, allowing businesses to access global markets by meeting the required regulatory standards of different countries.

- Compliance with Regulations: It ensures that products comply with various national and international regulations, including industry-specific standards like CE, FCC, or ISO, minimizing the risk of legal issues.

- Consumer Safety: The certification signifies that products are tested for safety risks, such as electrical hazards, toxic materials, or structural integrity, ensuring consumer protection.

- Sustainability Certification: Intertek offers certification for eco-friendly and sustainable products, helping companies meet environmental standards and reduce their ecological footprint.

- Boosts Consumer Confidence: Products with Intertek certification are trusted by consumers, enhancing brand reputation and increasing market competitiveness.

- Efficiency in Manufacturing: It helps streamline manufacturing processes by identifying areas for improvement, enhancing product consistency, and reducing production costs.

- Industry-Specific Solutions: Intertek certification covers various industries such as textiles, electronics, construction, food, and automotive, offering specialized testing and certification relevant to each sector.

- Risk Mitigation: By ensuring compliance with safety and regulatory standards, Intertek certification helps businesses avoid costly recalls, penalties, or reputation damage.

- Accelerated Time to Market: Intertek’s expertise in product testing and regulatory compliance speeds up the certification process, allowing manufacturers to launch products faster.

- Sustainable Business Practices: Certification programs like Intertek’s Green Leaf certification help businesses demonstrate their commitment to sustainability and responsible sourcing.

- Workplace Safety and Compliance: Beyond product testing, Intertek also offers certification for workplace health, safety, and environmental management systems, ensuring a safe and compliant work environment.

- Ongoing Audits and Testing: Regular follow-up audits and tests ensure that certified products and processes continue to meet established standards over time.

Competitive Advantage: Companies with Intertek certification are viewed as more credible and reliable in the marketplace, gaining a competitive edge over non-certified competitors.

Color Difference Test

- Consistency in Color Matching: Measures the difference between the target and actual color of a product, ensuring uniformity across batches and production lines.

- Brand Image Preservation: Essential for maintaining a consistent visual identity for brands, especially in textiles, packaging, or consumer goods.

- Consumer Satisfaction: Prevents discrepancies in color that could lead to consumer dissatisfaction, particularly for products where color is a key feature (e.g., fashion or interior design).

- Manufacturing Quality Control: Helps manufacturers detect variations in raw materials, processing conditions, or environmental factors that may affect color output.

- Regulatory Standards Compliance: Required for industries like automotive or paint manufacturing, where color consistency is regulated for aesthetic and safety reasons.

Shelf Life Test

- Longevity Prediction: Determines the estimated lifespan of a product by simulating long-term storage conditions such as temperature, humidity, and light exposure.

- Product Quality Assurance: Ensures that the product retains its intended quality and functionality throughout its intended shelf life, preventing degradation.

- Labeling Accuracy: Ensures that the stated expiration or use-by dates on products, especially food, pharmaceuticals, and cosmetics, are accurate and reliable.

- Reduces Waste: Helps companies optimize product packaging and formulation to extend shelf life, thereby reducing waste and losses due to expired products.

- Compliance with Regulations: Many industries require shelf life testing to meet regulations regarding product stability over time.

Environmental and Waterjet Tests

- Durability Assessment: Both tests measure how products perform under extreme environmental conditions (temperature, humidity, UV, and water pressure) to ensure long-term durability and reliability.

- Water Resistance Validation: The waterjet test evaluates a product’s ability to resist water penetration under high-pressure conditions, which is crucial for electronics, outdoor gear, and automotive components.

- Material Integrity: Both tests help verify that materials maintain their structural properties and performance when exposed to environmental stressors like moisture, heat, and water.

- Regulatory Compliance: Ensures products meet industry standards for environmental resistance and ingress protection, critical for certifications such as IP ratings or other safety regulations.

- Prevention of Field Failures: Identifies weaknesses in products that could lead to failure in real-world scenarios, reducing the risk of malfunctions or defects when exposed to harsh conditions.

- Product Suitability: Confirms that products are fit for use in specific environments, such as outdoor, industrial, or high-moisture settings, ensuring their safety and functionality for intended applications.